CNC MILLING

Milled parts

Highly complex CNC milled parts

milled into shape. Perfect fit.

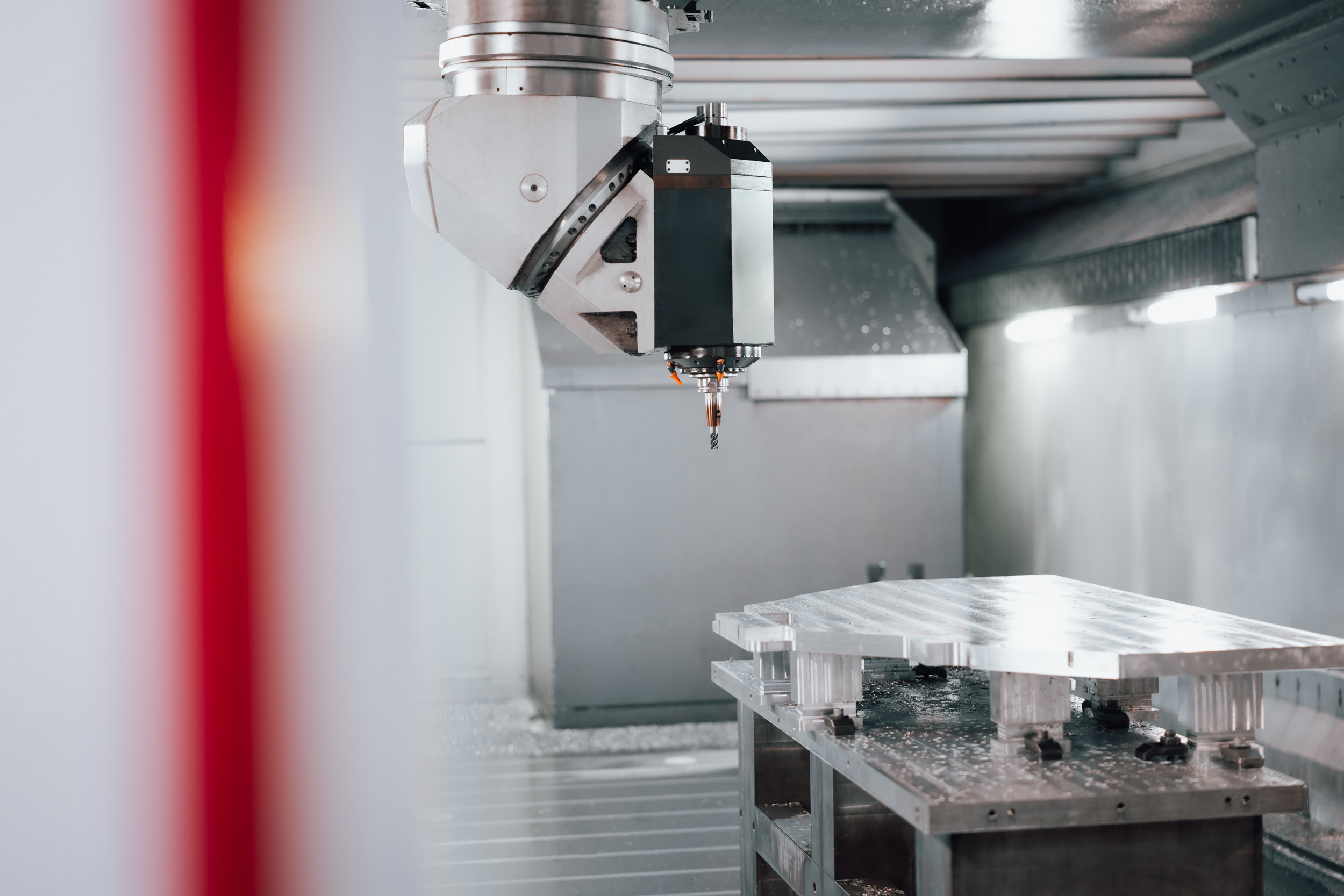

To manufacture your ambitious prototypes or series parts, we rely on the latest high-tech CNC machining centres, as well as universally usable 5-axis CNC milling machines.

Due to our enormous vertical range of manufacture and high productivity, we are able to produce both small and large milled parts with the highest precision and quality.

We mill almost all metallic materials, CFRP and other engineered plastics.

With our many years of experience and the high level of expertise of our skilled workers, we master workpieces with the most difficult geometries and push the envelope of what is achievable. High-precision milling, down to 0.3 µm. Within the desired deadline.

Your advantages at a glance

- Precise milling of highly complex and filigree geometries

- High capacity and productivity

- Unbeatable employee expertise in milling technology as a result of decades of experience

- Flexible and fast machining times

- Quality assurance for a dimensional accuracy of up to 0.3 µm

- 100 % air-conditioned production and assembly infrastructure

- Documentation of all dimensions and geometric tolerances

- Reproducible quality

- Certified in accordance with EN 9100:2018, including ISO 9001

Milling in XXL – machining of large parts

PRECISE. EFFICIENT. IN THE SHORTEST POSSIBLE TIME.

Do you need large-format milled parts for your ambitious development project?

With our 5-axis gantry milling machine, we are able to manufacture sheets and components made of aluminium and many other materials up to a dimension of

5,000 x 2,200 x 1,200 mm.

.

Machining options

- Maximum machining size

5.000 x 2.200 x 1.200 mm

Application

- Prototype machining/zero series production

- Small-batch production

- Production of medium batch sizes

Materials

- All aluminium alloys

- Magnesium

- Stainless steel, tool steel,

alloyed and unalloyed steels - Titanium

- Superalloys for high-temperature applications (e.g., mu-metal, various nickel alloys, Inconel, molybdenum, etc.)

- Non-ferrous metals

- Fibre reinforced plastics CFRP

- Engineered plastics

CNC AUTOMATION FOR SMALL SERIES

Our RS2 robot system, incl. handling system, enables us to operate 24/7. On highly dynamic CNC milling centres with pallet system and 228 tool stations each, we mill complex components in small series within the shortest possible time. Everything is geared towards producing your milled parts in series economically and in the best quality.

- Maximum machining size for rectangular workpieces:

14 – 126 mm x min. 20 mm x max. 190 mm - Maximum machining size for cylindrical workpieces:

26 – 126 mm x 190 mm - Maximum workpiece weight: 10 kg each

- Pallet handling: 150 kg

INFRASTRUCTURE

We mill using high-tech machines of the latest generations:

- • 6 CNC 5-axis machining centres, incl. robot systems

- 28 CNC 5-axis milling machines

- 6 CNC 3-axis milling machines

- 1 gantry milling machine FPT – Dinomax 1

Component finishing

We reliably meet additional requirements for dimensional and surface tolerances with sophisticated grinding technology.

Edge technologies

We handle surface treatment, heat treatment, welding, sheet metal forming and additive manufacturing with the help of specialised, certified partner companies.

SK TECHNOLOGY 4.0

Using transparent, digital precision technology, we master the most complex requirements in precision technology with the highest quality standards and ambitious delivery times.

Convinced? Then let’s talk.

We look forward to your project.

TEAM PROJECT MANAGEMENT

Tel. +49 (0) 9461 91106 – 0

E-Mail info@sktechnology.de